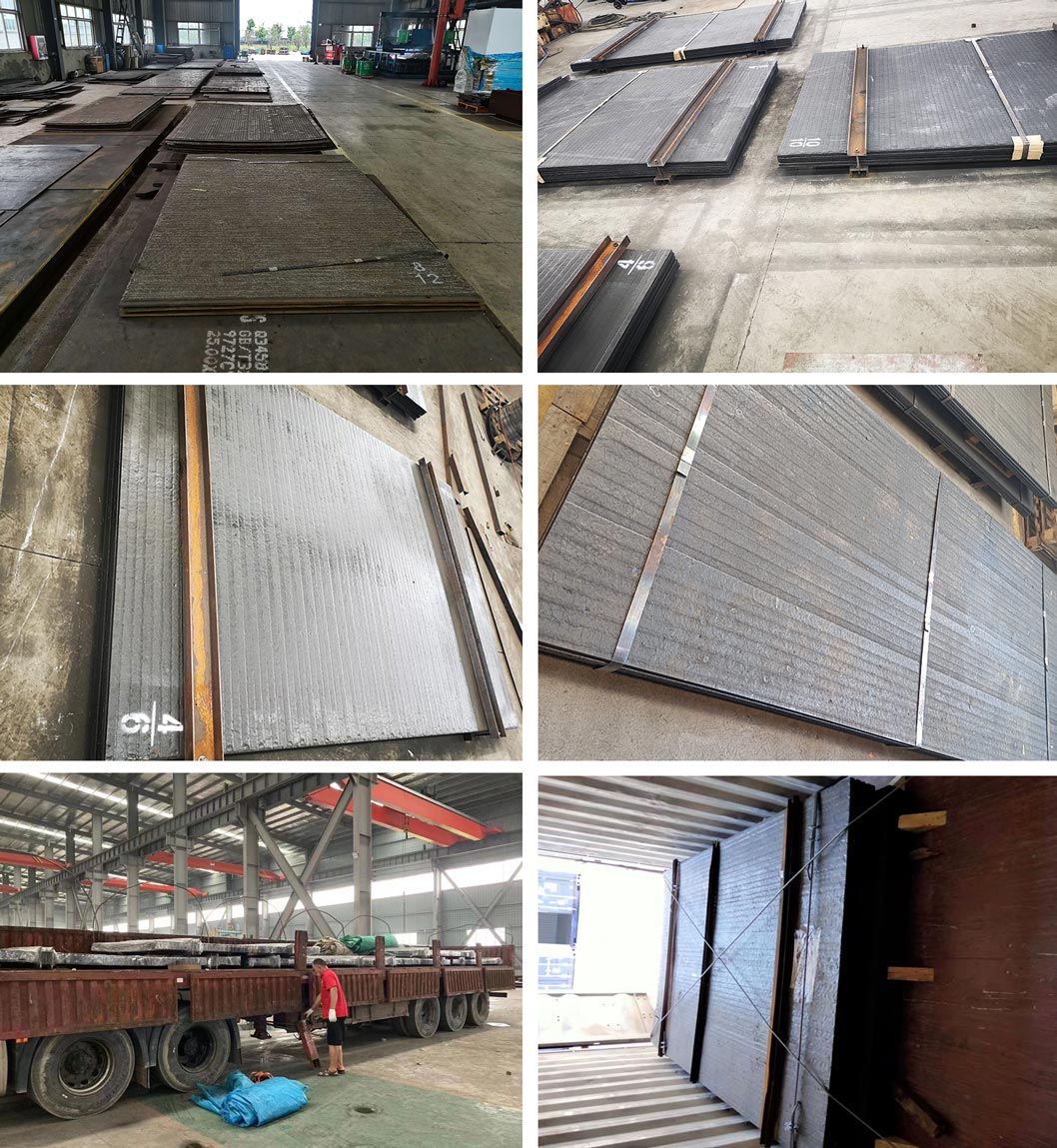

Chromium carbide overlay (CCO) wear plates

Thickness: 3+3, 4+4, 5+5, 6+6, 8+8, 10+10, 12+12

Size: 1400mm*2000mm, 1500mm*3000mm, 2000mm*3000mm and Customized Size

Video

SPESIFIKASI

| Chemical Composition of Deposited Metal (Wt%) | ||||||

| Thickness | C | Si | Mn | P | S | Cr |

| 3+3 | 3.5-4.5 | 0.4-1.2 | 0.4-1.0 | - | - | 19-22 |

| 4+4 | 3.5-4.5 | 0.4-1.2 | 0.4-1.0 | - | - | 19-23 |

| 5+5 | 3.5-4.5 | 0.4-1.2 | 0.4-1.0 | - | - | 20-23 |

| 6+6 | 3.5-4.5 | 0.4-1.2 | 0.4-1.0 | - | - | 24-38 |

| 8+8 | 3.5-4.5 | 0.5-1.2 | 0.5-1.0 | - | - | 27-31 |

We have equipped with our own developed wear plate hardfacing machine, including single torch, double torch and quadrule torch wear plate hardfacing machine, total 25 uints hardfacing machine.

Jinhua is able to experiment and effectively manufacture chromium carbide overlay (CCO) wear plates using open arc welding with advanced fusion welding technology.

As a result, Jinhua is able to apply highly wear-resistant chromium carbide to steel substrates. In addition, our team is able to produce consistent microstructures and chemicals at the edges.

Jinhua's Chrome Carbide Overlay wear plates are a unique Chrome Carbide overlay on a mild steel substrate designed for areas with severe impact and wear.Jinhua can form, roll and cut to your specific needs.

KEUNGGULAN

Jinhua's chromium carbide composite steel plates offer outstanding strength and corrosion resistance. This bi-metallic product begins with a mild steel base plate, which is then fused to the chromium carbide steel by welding. With up to 32% chromium (Cr) and up to 5.8% carbon, chromium carbide metallurgy is bonded to the surface of the steel, creating a protective and durable surface that will not separate from the base metal.

Chrome carbide overlay steel is extremely hard, both wear and impact resistant, and can withstand high temperatures. As a result, Jinhua's composite plates are ideal for extreme wear applications, high temperature environments and where corrosion is a problem. The chrome carbide overlay coating also provides a high level of impact resistance.

On average, 4 to 6 times longer life than AR steel

Fast return on investment

Excellent resistance to chipping, spalling and separation

Abrasion resistance up to 1,250º F

Available in a variety of thickness combinations

Maximum wear resistance

Multiple grades

Made in China, cost effective

Cost-effective solution compared to conventional wear-resistant steels

Recommended for resistance to wear, micro-movement, cavitation and particle erosion in high temperature applications (up to 1100°F)

Suitable for mild to moderate impact wear resistance

Low maintenance and easy to install.

The cover of the CCO plate will consist of a series of beads with numerous fine line cracks. These properly spaced cross-check cracks are a natural phenomenon and are beneficial to the material. The cracks propagate through the overlay and end at the fusion line.

TAGS

Copyright © Jinhua (Qingdao) Hardfacing Technology Co., Ltd. Seluruh hak cipta |

Sitemap

| Dukungan teknis: